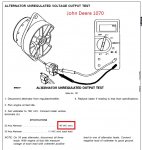

Swapping a first generation motor into a 2nd generation tractor. Older motor has a 3 wire dyno existing motor has a 2 wire dyno. Thinking the regulator and wiring must go with the existing dyno right?

Managed to get the dyno off the existing motor using a gear wrench on that lower middle nut one click at a time. Can imagine what kind of chore it is going to be to get that nut back on. Any tricks?

Thanks, the saga continues...

Managed to get the dyno off the existing motor using a gear wrench on that lower middle nut one click at a time. Can imagine what kind of chore it is going to be to get that nut back on. Any tricks?

Thanks, the saga continues...