Okay, take two, rewriting the DIY here with the corrections from eserv in

post #11

Land Pride 380-137A 3rd Function for BX

put the tractor up, take off rear right wheel...

There is some conflicting information, the Land Pride 380-137A instructions say to "hook up to the power beyond from the loader valve". However, there is another set of "dealer instructions" from Land Pride specific to the 2360 and 2370 series that say to hook up to the

pump outlet on the rear block, with a clear corresponding photo. I originally hooked up the unit to PB, but changed it to the pump port. Pump port instructions follow.

You remove the metal hydraulic line from Pump outlet to where it connects to the next line just forward of the fan. In the photo below it is the line next to and immediately behind the one marked with red.

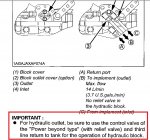

Under the foot deck, forward of the fan, the pump line is marked in blue (power beyond marked in red shown with a plug in it). There is very little room here. I did not have wrenches small enough to fit in this space. Removing the foot deck takes all but 15 minutes, just a few nuts and its up out of the way. Lots of room now.

from above. (shown with hose already attached)

this section of the pump line comes out

You attach the long 62" hose to the line under the tractor, and the other end of this hose goes to the "T" Port on the valve body. The hose will travel back, loop up and inside the frame, it will go between the frame and the existing metal lines, keeping it well clear of the fan.

The 42" hose goes from the P port on the valve body to the Pump port at the block on the rear.

There was barely enough hose length, I had a few more inches to work with, and no tension on the connections, if I ran the hoses straight down from the valve through the brake pedal slot under the foot deck. There is enough room to keep the hoses clear even if full brake travel is applied.

Continued below...