A am planning on installing some lights on the ROPS of my new L3200. I am going to make a mounting bracket to attached the lights so no holes will be drilled into the ROPS. I want to mount 2 trapezoidal lights facing forward and 1 flood light facing to the rear and have them both on separate switches. All 3 lights are 55 watt Blazers from Tractor Supply. I am no electrical genius so I’m looking for some advice on how to wire them so that the switches will only work when the ignition is turned. Does anyone have any advice on how to go about this? Another thing I was wondering is what size wires to use. The wires on the existing lights seem really small. Photos and sketches would be great.

Auxiliary Light Wiring

- Thread starter qball

- Start date

bcbull378

Member

Equipment

GL3830,fel,brush hog,pallet forks,disc,gannon,auger,springtooth,plow,drag,ripper

Here are a few pictures of how I mounted lights on my L3830 as for the wiring I conected to the large wire going to the back of the fuse block( only hot when key is on ) and then fused both front and rear lights on seperate inline fuses and seperate switches. i made the mounting bracket out of a piece of flat stock. I went with 2 front and 2 rear I like lots of light and I must say they work great.

Attachments

-

94.7 KB Views: 5,743

-

35.9 KB Views: 5,750

-

52.5 KB Views: 5,426

Good stuff !!! I need to do the same thing, but figuring out how is the key !!! I am electrically challenged !!! and HEY, this it my FIRST post !!!

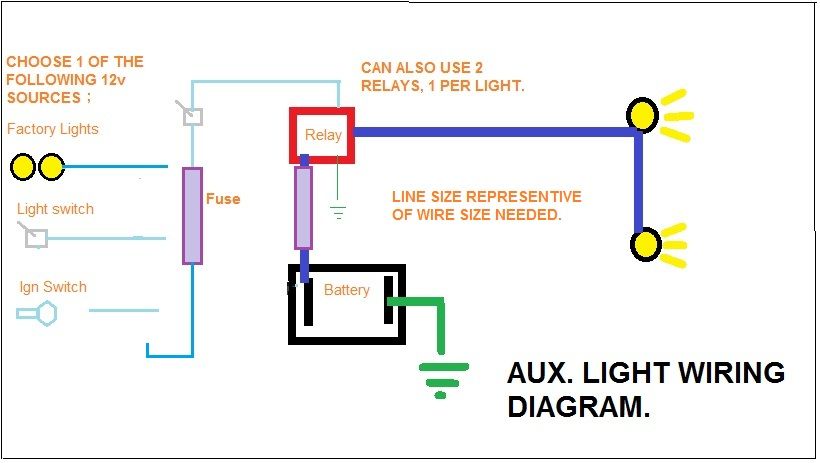

First, always use fuses.

second, always use relays.

third, always use the appropriate gauge wire.

optional- switches, split wire loom, indicator lights, cable ties, wire connectors, etc.

If your headlight switch works, it can do all the work, if you want all lights on at once. There is not any reason to attach anything to the Ignition switch, its already done for you. (wire to your headlights)

To simplify, mount relays run a heavy wire to your lights to the relay then to the fuse then to batt. Follow the diagram on the relay, goes to the two switch lugs. Now a trigger wire, light gauge is all that is needed, 14ga-16ga, as it will carry only a low amount of milliamps. splice into the headlight wire and run to the coil side of the relay. if you want a switch put it in this line, a dash indicator light can be add to the out side of the switch if wanted. now from the other coil side of the relay to a GOOD ground.

From here you could do many options, multiple relays (a good idea) multiple switches to split the separate relays into light groups. also splits the load up.

Doing it this way, keeps the heavy load carrying wire to a min. length so its more efficient. keeps you from messing with the Ign. circuit to stop reliability issues. its also the way the auto makers do it. they just use a dash switch as the trigger wire, which you could do as well. but my way, you kill the tractor, turn the Ign switch off it also kills all the lights to save your Batt. an over ride switch can be added easily.

many many options can be done. Have specific questions or options, I'd be happy to help out. Yes, I was a licensed master electrician.

This is not the only way, its my way to keep the circuits efficient and safe. while keeping the reliability of the tractor. Yes, 12 volts DC can make a big fire! do it safe if you do it.

Post here or PM me.

second, always use relays.

third, always use the appropriate gauge wire.

optional- switches, split wire loom, indicator lights, cable ties, wire connectors, etc.

If your headlight switch works, it can do all the work, if you want all lights on at once. There is not any reason to attach anything to the Ignition switch, its already done for you. (wire to your headlights)

To simplify, mount relays run a heavy wire to your lights to the relay then to the fuse then to batt. Follow the diagram on the relay, goes to the two switch lugs. Now a trigger wire, light gauge is all that is needed, 14ga-16ga, as it will carry only a low amount of milliamps. splice into the headlight wire and run to the coil side of the relay. if you want a switch put it in this line, a dash indicator light can be add to the out side of the switch if wanted. now from the other coil side of the relay to a GOOD ground.

From here you could do many options, multiple relays (a good idea) multiple switches to split the separate relays into light groups. also splits the load up.

Doing it this way, keeps the heavy load carrying wire to a min. length so its more efficient. keeps you from messing with the Ign. circuit to stop reliability issues. its also the way the auto makers do it. they just use a dash switch as the trigger wire, which you could do as well. but my way, you kill the tractor, turn the Ign switch off it also kills all the lights to save your Batt. an over ride switch can be added easily.

many many options can be done. Have specific questions or options, I'd be happy to help out. Yes, I was a licensed master electrician.

This is not the only way, its my way to keep the circuits efficient and safe. while keeping the reliability of the tractor. Yes, 12 volts DC can make a big fire! do it safe if you do it.

Post here or PM me.

Last edited:

76_Bronco

Member

Equipment

B7200 4WD w/FEL, 4' disc, 4' Brush Hog, 14" Plow, 4' Blade, JD 246 2 row Planter

x2 on everything Kytim said. Relays are very simple to wire in, and they don't put any strain on the existing wiring and switches. The last one I purchased was less than $5 at the parts store.

If I remember correctly each 55W light should pull about 5 amps, so size wire and fuses accordingly.

gpreuss

New member

Lifetime Member

Equipment

L3200DT w/FEL, K650 Backhoe, 5' Rotary, 40" Howard Rotavator, 6' Rhino blade

The work lights are on when the tractor is running. With two lights and the supplied 10A fuse, as soon as I hit the gas the fuse blew. I went to a 15A fuse and have had no problems. I would not want to run 3 lights at once - you would need a 20A fuse, and eventually I think the wiring would prove inadequate.

For my installation, I mounted the lights to one side of the canopy frame. I put a toggle switch by the lights - most of the time you do NOT want them. I would consider having a switch for each light, and only use two at a time.

In rgw fuse block photo I have an external fuse/holder, wired to a motorcycle 12V receptacle, and to the battery terminal of the starter. I have since replaced this with a sealed holder. This is a reasonable alternative fusing method, but the wiring is hot all of the time, and you would have to make a longer wire run from the gass tank area back and up to the ROPS.

When I did all of this it was about 10 deg out, so it is not as neat as it could be. The wiring is well protected and dry, however.

I hope this helps.

Gil

Attachments

-

50.6 KB Views: 4,055

-

44.7 KB Views: 5,563

-

59.9 KB Views: 4,605

-

43.5 KB Views: 4,404

I figured that I'd tack on to this thread rather than starting another one.

I'm in the process of adding to aux lighting circuits, one for front lights and one for rear lights. I've tried tapping off a 12v wire that is switched via the IGN from/to the OPC wire harness (small Red/White wire) on my B7800. When I do this I blow the fuel relay and dash light fuses!

Here is a schematic on how I'm wiring things:

The relays (the square blocks) are Echlin 5 pin from NAPA (part # on box AR274), which is a Bosch style. Relay wiring harness, also from NAPA ("Crankin' Power AS-1217) is Bosch compatible The switches are Cole Hersee ON-OFF, also from NAPA (part # on box 5582-10-BX).

My understanding is that it doesn't matter whether pin 85 or 86 is used for ground (and or the 12v input). That is, I can run 12v to 86 and 85 to gnd, or, run 12v to 85 and 86 to gnd.

I've verified continuity (except the final output, as these are yet to be hooked up). Power as a strong 12.47v coming to pin 30 (Blue wire in wiring harness). Toggle switches are doing what they're supposed to: reading through the relay wiring harness across pins 85 & 86 (White and Black wires on wiring harness) make and break across the switch fine. And on the relays themselves I see continuity across pins 85 & 86; I don't, however see any across 30 and 87b (which I thought I should - I know that there shouldn't be any across 30 and 87 as 87 is normally open).

I'm in the process of adding to aux lighting circuits, one for front lights and one for rear lights. I've tried tapping off a 12v wire that is switched via the IGN from/to the OPC wire harness (small Red/White wire) on my B7800. When I do this I blow the fuel relay and dash light fuses!

Here is a schematic on how I'm wiring things:

The relays (the square blocks) are Echlin 5 pin from NAPA (part # on box AR274), which is a Bosch style. Relay wiring harness, also from NAPA ("Crankin' Power AS-1217) is Bosch compatible The switches are Cole Hersee ON-OFF, also from NAPA (part # on box 5582-10-BX).

My understanding is that it doesn't matter whether pin 85 or 86 is used for ground (and or the 12v input). That is, I can run 12v to 86 and 85 to gnd, or, run 12v to 85 and 86 to gnd.

I've verified continuity (except the final output, as these are yet to be hooked up). Power as a strong 12.47v coming to pin 30 (Blue wire in wiring harness). Toggle switches are doing what they're supposed to: reading through the relay wiring harness across pins 85 & 86 (White and Black wires on wiring harness) make and break across the switch fine. And on the relays themselves I see continuity across pins 85 & 86; I don't, however see any across 30 and 87b (which I thought I should - I know that there shouldn't be any across 30 and 87 as 87 is normally open).

I need to verify this*, but it looks like, contrary to what I'd read about relays that pins 85 & 86 were interchangeable, the relays that I got have internal diodes and that that means pin 85 HAS to be to ground.

* Having a hard time finding info on-line. Maybe this is obvious on the relay's diagram (will check): I'm not an electronics wiz.

Here's a great write-up on all this:

http://www.jeepforum.com/forum/f11/headlight-harness-upgrade-confusion-572769/#post5363228

I suspect that if I change pins 85 & 96 and use new relays (diodes on the first set cooked) that all will be well.

NOTE: I'm bothering to post all of this in the hopes that some other poor schmuck like me who does something like this might be able to catch all of this from a simple web search.

* Having a hard time finding info on-line. Maybe this is obvious on the relay's diagram (will check): I'm not an electronics wiz.

Here's a great write-up on all this:

http://www.jeepforum.com/forum/f11/headlight-harness-upgrade-confusion-572769/#post5363228

I suspect that if I change pins 85 & 96 and use new relays (diodes on the first set cooked) that all will be well.

NOTE: I'm bothering to post all of this in the hopes that some other poor schmuck like me who does something like this might be able to catch all of this from a simple web search.

My L35 has one empty wire connector at the rear on each side of the tractor just behind the seat and part of the wiring harness to the tail lights marked "do not exceed 8 amps" These are for work lights which I installed 2 LED's one on each line and put a toggle switch on each light bracket. They are already fused with a 10 amp fuse each in the fuse block and do not come on unless the key is on. No relays, no extra fuses, no special wiring. Very simple and lots of light. Have a look under your seat next to the fenders. You may have something similar.

I've got everything working now, after replacing the fried relays: diodes killed- I will remove them or perhaps replace them and use them for some other future project. Lesson learned: not all relays are created equal; those with diodes can ONLY be wired one way.

I went with the alternator upgrade kit because 18amps is just too limiting, LEDs or otherwise. Also, I break stuff, and the thought of breaking expensive lights -LEDs- isn't something I want to experience (Mr Murphy would ensure that such breakages would occur at the most inconvenient time): I can find, and buy, cheaper lights quite easily.

Anyone with a similar tractor is free to contact me for information (have pictures) of how I did things (mounting relays; light mounts etc.).

Again, my point here in ressurecting all of this was to leave a "crumb" for someone like myself who might venture on all of this.

I went with the alternator upgrade kit because 18amps is just too limiting, LEDs or otherwise. Also, I break stuff, and the thought of breaking expensive lights -LEDs- isn't something I want to experience (Mr Murphy would ensure that such breakages would occur at the most inconvenient time): I can find, and buy, cheaper lights quite easily.

Anyone with a similar tractor is free to contact me for information (have pictures) of how I did things (mounting relays; light mounts etc.).

Again, my point here in ressurecting all of this was to leave a "crumb" for someone like myself who might venture on all of this.