No, on kubota's they are an open loop system, all fluid flows thru the pressure relief valves not around them,

I beg to differ. This is from the B7100 WSM:

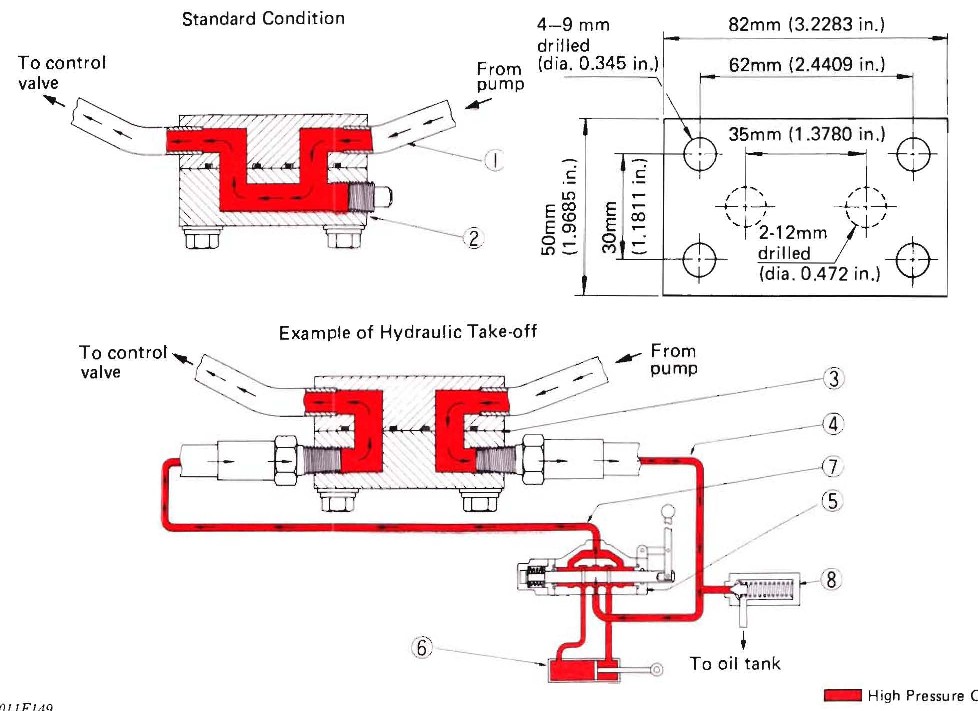

Note the pressure relief valve location -- #8, between the supply from the pump and discharging into the tank. Fluid flows continuously through the open centre spool valve, but no fluid flows through the relief valve unless the pressure exceeds the relief valve setting.

Similarly, please study this page from the L3540 WSM:

Again, the relief valve is between the pump outlet and the tank inlet.

The difference between a closed centre system and an open centre system is that the closed centre system maintains maximum pressure in the lines to the control valve at all times -- the oil does not circulate through the system when the control valve is in neutral because the closed spool centre blocks the flow.

Conversely, an open centre system has variable pressure in the lines. When the control is in neutral the oil flows through the open centre to the tank. When the control is operated, the centre is closed as the spool diverts the oil flow to the selected cylinder port, and line pressures rise as the cylinder meets resistance. When the cylinder reaches the end of it's travel, the system is effectively dead-headed -- the fluid has no place to go.

The pressure would continue to climb until something burst, except for the presence of the relief valve. When the pressure reaches the set-point of the relief valve, it overcomes the resistance of the relief valve spring and the pressure is kept within the safe limits by bleeding fluid to the tank.

Piping a relief valve in the middle of the tank return line not only provides no protection for the cylinders, it would serve to restrict the flow from the spool valves to the tank, as fluid would have to overcome the relief valve spring pressure to allow any flow.

Ok, now how does this apply to the problem at hand?

The force that can be applied by a cylinder is equal to the fluid pressure times the surface area of the piston. But the two ends of the cylinders have two different effective piston areas, because one side of the piston is connected to the rod. No fluid can push on the area covered by the rod connection. So, for a given fluid pressure, the cylinder will have more extension force than retraction force. Similarly, it takes more fluid to fully extend the cylinder than it takes to retract the cylinder.

Finally, for a double-acting cylinder to move, fluid must return to the tank from the opposite side of the cylinder. If the fluid return is restricted, the cylinder will be fighting itself. Under that condition, extending the cylinder will go faster than retracting the cylinder because of the difference in area (and therefore force applied) between the two sides of the piston. When retracting the cylinder, there's a double whammy: not only does the smaller area have to overcome greater force, but at the same time it must return a greater quantity of fluid to the tank!

The configuration on Crazy Horse's machine is typical: extending the boom cylinders raises the boom. Extending the bucket cylinders dumps the bucket. He indicates that both those actions seem to work comparatively well. But actions requiring cylinder retraction -- lowering the boom or curling the bucket up -- are very slow.

If you are correct that there is a relief valve installed inline between the control and the tank (and I see no reason to question it), then I believe that would fully explain his symptoms, because returning fluid would be restricted by the relief valve spring pressure.

EDIT: I just saw Crazy Horse's sketch. If the "rear end" fitting is a relief valve, then it's not in-line. It's exactly where it's supposed to be. Likely the setting is just too low. Capping that off is a BAD IDEA -- it's the safety that protects the rest of the system

!!!