I was lucky enough to find a "new old stock" loader for my L3750. The loader is a Woods LC108. Unfortunately I don't have the bucket. I do however have a new Kubota brand bucket. I can fabricate brackets to make it fit the LC108 but have no pattern for the pin placement. The width obviously is predetermined by the loader arms but I do not know the distance between the lift arm pins and the tilt cylinder pins. I would like to get it close to factory spec so the leverage will be correct. Does anyone have an LC108 or LC112 that could measure for me? Woods will not share the info and I have not found anything on local dealer lots to copy.

mounting loader bucket

- Thread starter jsmootz

- Start date

I"m not familiar with your tractor or FEL but I can tell you that the placement of those pin-holes are important. In particular, you'll want to insure that the lower hole is sufficiently "aft" (towards the FEL) a bit more than the top hole, or two things can occur: The bucket will not tilt sufficiently back to please you, and the "nose" of the lower FEL arm will not enter between the brackets sufficiently to properly fit. (Made certain the bracket has sufficient "depth" at the bottom hole to allow your lower lift arm to fully enter without contacting the back of the bucket.)

Here's pics of my LA1002 FEL and it's bucket. The distance between the holes are 10-7/16" center to center. The width of the bracket and distance of holes from the back of the bucket are shown. (Sorry one of the pics is upside down... I actually corrected that and reloaded it...and it still posted upside-down... but you can still get the width.)

Another thing: My pins are 30mm (1-3/16") but may be unusual. You'll want to get your pin size from your FEL. I had a devil of a time obtaining 30mm pins but found out that Kubota's excavator uses that size. McMaster-Carr also sold me some rod/stock that size so I can make addt'l pins if I want. Hopefully yours are a more common size.

Here's pics of my LA1002 FEL and it's bucket. The distance between the holes are 10-7/16" center to center. The width of the bracket and distance of holes from the back of the bucket are shown. (Sorry one of the pics is upside down... I actually corrected that and reloaded it...and it still posted upside-down... but you can still get the width.)

Another thing: My pins are 30mm (1-3/16") but may be unusual. You'll want to get your pin size from your FEL. I had a devil of a time obtaining 30mm pins but found out that Kubota's excavator uses that size. McMaster-Carr also sold me some rod/stock that size so I can make addt'l pins if I want. Hopefully yours are a more common size.

Attachments

-

89.5 KB Views: 393

-

86.7 KB Views: 397

-

90.6 KB Views: 475

-

86.2 KB Views: 565

Last edited:

I replaced my bucket on my Kubota B219 with a Branson or MF bucket from a dealer that carried both.

The cylinder needs to be able to fully retract & extend so do pay attention to the curl & dump positions. Use a template profile so you can visualize everything through the entire range. I had to adjust mine slightly so that the rods won’t touch anything.

Sent from my iPhone using Tapatalk

The cylinder needs to be able to fully retract & extend so do pay attention to the curl & dump positions. Use a template profile so you can visualize everything through the entire range. I had to adjust mine slightly so that the rods won’t touch anything.

Sent from my iPhone using Tapatalk

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Not to be a smart guy...but changing it to SSQA would be a much better option.

Now for a couple things I discovered about woods loaders and buckets:

Pin spacing is only one hurdle, pin height off the bottom and I would not count on your back plate of the Kubota bucket to be the same angle as the woods bucket.

These differences will determine if it's even usable, woods angle is a standard angle the same as all SSQA buckets.

If the kubota bucket you have was a cylinder to bucket direct attach without the compound links you'll probably need to rework the entire mount, again see first statement.

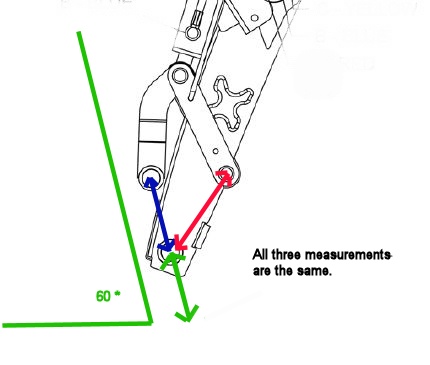

Now for determining the distance of the pins:

It's the same distance for the blue line pin spacing as it is for the red line pin spacing, the bottom pin from the ground is the same as the red measurement measured at 60 degrees back, it's a mathematical box arrangement.

Do not match the distance up the back link as it will not match any measurements.

And for angle of the pins with the bucket on the ground and level, 60 degrees forward.

Now for a couple things I discovered about woods loaders and buckets:

Pin spacing is only one hurdle, pin height off the bottom and I would not count on your back plate of the Kubota bucket to be the same angle as the woods bucket.

These differences will determine if it's even usable, woods angle is a standard angle the same as all SSQA buckets.

If the kubota bucket you have was a cylinder to bucket direct attach without the compound links you'll probably need to rework the entire mount, again see first statement.

Now for determining the distance of the pins:

It's the same distance for the blue line pin spacing as it is for the red line pin spacing, the bottom pin from the ground is the same as the red measurement measured at 60 degrees back, it's a mathematical box arrangement.

Do not match the distance up the back link as it will not match any measurements.

And for angle of the pins with the bucket on the ground and level, 60 degrees forward.

Attachments

-

39.2 KB Views: 2,372

Last edited:

Scott, while reading the posts made after mine I realized I made a "typo" earlier, in that I first said the distance between my pin holes was 10-1/16". That was incorrect, and I've edited my previous post to reflect the actual measurement, which is 10-7/16" from pin center to center.

NIW suggested a SSQA...but I looked into that and was turned off by the cost of the set-up to convert from pin-on to SSQA. (It requires not only the adapter, but also to cut off the brackets of my bucket and weld on SSQA brackets. It came to thousands of dollars and that was ridiculous in my view.

I found a youtube video of a guy who makes a very simple QA that makes ordinary pin-on attachments into QA without a bunch of money or trouble. https://www.youtube.com/watch?v=KuktqggNDCw

The guy who made mine is Dan Heibert: danannah (at) gmail.com

ph: 20four-362-798four (Manitoba)

He made mine and shipped them and accepted paypal. (about $400 but mine were special one-off/custom-made due to special dimensions on my rare FEL.)

They are the cat's meow and didn't require me to modify anything. I leave the top pins in my attachments (bucket and pallet-forks mostly but ordinary pin-on attachments work without further expense or modification) and pick them up with the FEL and then install the lower pins ...and go to work! A few minutes to switch and no help required.

This is how they arrived, but Of course, I painted them orange.

NIW suggested a SSQA...but I looked into that and was turned off by the cost of the set-up to convert from pin-on to SSQA. (It requires not only the adapter, but also to cut off the brackets of my bucket and weld on SSQA brackets. It came to thousands of dollars and that was ridiculous in my view.

I found a youtube video of a guy who makes a very simple QA that makes ordinary pin-on attachments into QA without a bunch of money or trouble. https://www.youtube.com/watch?v=KuktqggNDCw

The guy who made mine is Dan Heibert: danannah (at) gmail.com

ph: 20four-362-798four (Manitoba)

He made mine and shipped them and accepted paypal. (about $400 but mine were special one-off/custom-made due to special dimensions on my rare FEL.)

They are the cat's meow and didn't require me to modify anything. I leave the top pins in my attachments (bucket and pallet-forks mostly but ordinary pin-on attachments work without further expense or modification) and pick them up with the FEL and then install the lower pins ...and go to work! A few minutes to switch and no help required.

This is how they arrived, but Of course, I painted them orange.

Attachments

-

13.1 KB Views: 963

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

My SSQA cost me about $300 in total, yes all new parts.NIW suggested a SSQA...but I looked into that and was turned off by the cost of the set-up to convert from pin-on to SSQA. (It requires not only the adapter, but also to cut off the brackets of my bucket and weld on SSQA brackets. It came to thousands of dollars and that was ridiculous in my view.

I now can use one or 10 different implements on the front of the tractor and bobcat.

You do realize you dimensions that you gave him are worthless right, he does not have a kubota loader, nor does he have a cylinder to bucket attachment like yours, so none of the dimensions are the same as his setup.

Last edited:

GreensvilleJay

Well-known member

Equipment

BX23-S,57 A-C D-14,58 A-C D-14, 57 A-C D-14,tiller,cults,Millcreek 25G spreader,

The one BIG reason I bought the BX23S over the BX25 WAS the SSQA setup. I've already bought an HLA pallet fork unit and thilled with the easy chnging of implements. Instead of fighting to get a job done, simply using the right tool for the job makes it fun an d easy, and SAFE.

I suspect someone makes a SSQA adapter for your loader, use google 'loader name ssqa adapter' and see what comes up.

I have an Allis-Chalmer D-14 with full hydraulic pinned bucket collecting dust as it was a pain to remove and pin on the forks.

I suspect someone makes a SSQA adapter for your loader, use google 'loader name ssqa adapter' and see what comes up.

I have an Allis-Chalmer D-14 with full hydraulic pinned bucket collecting dust as it was a pain to remove and pin on the forks.

Recent/Current production tractor/FEL models are already SSQA compliant. But older models that are not already SSQA cost a LOT more than that. To convert only one item, say a bucket, from pin on to SSQA would require cutting off the bucket brackets, welding on the SSQA, and then converting the FEL also to SSQA, which easily adds up to over Two Grand. And if a compact tractor is the victim, then the weight of that SSQA must be deducted from the already small lift capability.My SSQA cost me about $300 in total, yes all new parts.

I now can use one or 10 different implements on the front of the tractor and bobcat.

You do realize you dimensions that you gave him are worthless right, he does not have a kubota loader, nor does he have a cylinder to bucket attachment like yours, so none of the dimensions are the same as his setup.

Yes, I realized he hasn't comparable equipment to mine, but he wanted measurements as a starting point and no one yet was stepping up to help him. I felt my pics and measurements would at least provoke the thoughts and considerations he'd be facing, and they led to my solution of a simpler and lighter and less expensive QA method.

Of course the route I chose only works for someone who plans a few attachments they already have. Someone just getting into the game planning many future attachment acquisitions, and with deeper pockets can go the SSQA route.

Yep. I had a pin on bucket and a pin on pallet fork, and it took almost a full hour to switch them, and another hour to put them back as before... getting on the tractor, ...getting off the tractor...getting on the tractor.... ad nauseum....I have an Allis-Chalmer D-14 with full hydraulic pinned bucket collecting dust as it was a pain to remove and pin on the forks.

The QA really made things workable. The switch happens in 2 or 3 minutes.

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

My Tractor and loader are 29+ years old, no where near recent or current.Recent/Current production tractor/FEL models are already SSQA compliant. But older models that are not already SSQA cost a LOT more than that.

Yes the loader Woods 1016 Loader is somewhat already SSQA compliant as it already has the proper angle on the back of the bucket but that's about it.

All my parts were bought off suppliers and fitted up.

I only made one small boo boo, I made square latch pins, I would do round latch pins if I did it again.

I didn't lose any noticeable lift capacity and my pivot point remained the same, so the added 100lbs of steel didn't do a lot of damage.

Granted I have all the tools to cut, weld, and fabricate so I'm a little ahead of the game.

Attachments

-

63.7 KB Views: 2,073