GR2110 Diesel Steer Cylinder Mounts Broken

I bought this machine new from my local dealer. Just out of warranty the hydrostat began hemorrhaging fluid. The service manager at the dealer tried blowing smoke up my, ahem, anyway, I came away feeling as if they were trying to stroke me. Fixed the problem myself (a seal was leaking) and found evidence that the assembly of the hydrostat was poorly done as I found a bunch of sealer squeeze out in the screen.

That was a couple years ago, and it has been running OK since.

I do all the maintenance myself (after all, I held ASE Auto and Truck Master certifications, was a certified Mobile Fluid Power Specialist, and have a lifetime of experience as a mechanic). Filters, fluids, grease where and when needed, sharpen, balance and change blades, clean chaff from radiator, check and adjust tire pressures, etc.

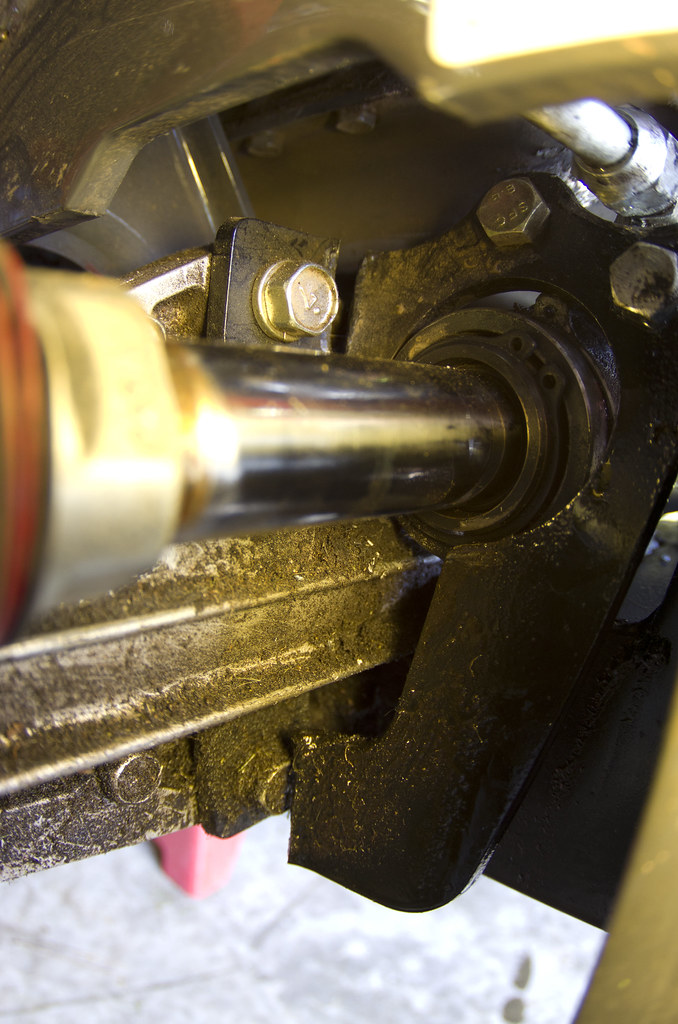

So today Mrs. Racer hopped on the thing to finish mowing the yard and came in to the shop a short while later telling me the thing started making a weird noise. I went out and had a look, and discovered the brackets holding the steer cylinder to the axle have broken, and the floating freely in front of the axle.

I searched the web, and then this forum, and it looks like I am the only guy in the world who has this problem.

In fact, when the seal gave up I felt the same way.

I take excellent care of all of my machines. I am a competent mechanic and my shop is very well equipped (its even bigger than my house). This clearly is nothing that I cannot repair, but still, I bought the Kubota based on the reputation of the brand. My experience this far would indicate I made a bad choice.

Convince me that I shouldn't fix this lemon and ditch it for a green tractor.

tractor.

After I get it torn down I'll post some photos.

I bought this machine new from my local dealer. Just out of warranty the hydrostat began hemorrhaging fluid. The service manager at the dealer tried blowing smoke up my, ahem, anyway, I came away feeling as if they were trying to stroke me. Fixed the problem myself (a seal was leaking) and found evidence that the assembly of the hydrostat was poorly done as I found a bunch of sealer squeeze out in the screen.

That was a couple years ago, and it has been running OK since.

I do all the maintenance myself (after all, I held ASE Auto and Truck Master certifications, was a certified Mobile Fluid Power Specialist, and have a lifetime of experience as a mechanic). Filters, fluids, grease where and when needed, sharpen, balance and change blades, clean chaff from radiator, check and adjust tire pressures, etc.

So today Mrs. Racer hopped on the thing to finish mowing the yard and came in to the shop a short while later telling me the thing started making a weird noise. I went out and had a look, and discovered the brackets holding the steer cylinder to the axle have broken, and the floating freely in front of the axle.

I searched the web, and then this forum, and it looks like I am the only guy in the world who has this problem.

In fact, when the seal gave up I felt the same way.

I take excellent care of all of my machines. I am a competent mechanic and my shop is very well equipped (its even bigger than my house). This clearly is nothing that I cannot repair, but still, I bought the Kubota based on the reputation of the brand. My experience this far would indicate I made a bad choice.

Convince me that I shouldn't fix this lemon and ditch it for a green

After I get it torn down I'll post some photos.

Last edited: