Hi Gang!

I got a B6200 and I'm using a hand grease-gun.

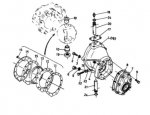

I'm working on greasing the front turn axles for the front tires.

I keep pumping, but I don't seeing any grease coming out anywhere.

How do I know if I'm actually pumping grease into it?

Thanks!

GotB6200 :-]

I got a B6200 and I'm using a hand grease-gun.

I'm working on greasing the front turn axles for the front tires.

I keep pumping, but I don't seeing any grease coming out anywhere.

How do I know if I'm actually pumping grease into it?

Thanks!

GotB6200 :-]