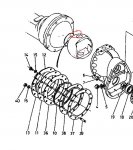

With the front wheels off I noticed a leak on the drivers side and it seems to be coming

from the axle case spindle housing. I need to do some cleaning to confirm.

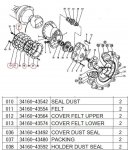

After checking with the local Kubota dealer it appears that most all of the parts needed to

do this repair are discontinued!

ITEMS CIRCLED IN RED ARE DISCONTINUED

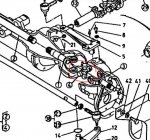

Wondering if anyone has any expertise in this area and has had to go the route of making

any of the required components to stop a leak?

It looks like a felt ring (id, od, thickness?), a dust seal (id, od, thickness, made of what?)

and a packing (gasket) are the wear items.

Attachments

-

90.7 KB Views: 911