I have been looking for some time now and I cannot find it.

I have a L3450, the gears grind a little when I shift the PTO to 540 RPM. I have wanted to adjust the clutch ever since I first acquired this machine.

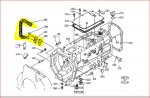

The manual say to remove the cover on the right side of the flywheel housing. I cannot find this cover. I have removed the sheet metal from around the steering wheel all the way down to the floor, I do not see it.

Can some one give me a hint?

Boyde

I have a L3450, the gears grind a little when I shift the PTO to 540 RPM. I have wanted to adjust the clutch ever since I first acquired this machine.

The manual say to remove the cover on the right side of the flywheel housing. I cannot find this cover. I have removed the sheet metal from around the steering wheel all the way down to the floor, I do not see it.

Can some one give me a hint?

Boyde