Creature Meadow

Well-known member

Lifetime Member

Equipment

2012 L4600, Disk, Brush Hog, GB60 Garden Bedder, GSS72 Grading Scraper

Okay guys and gals educate me.

I have read many posts on the use and brands of QH but have not seen this discussed.

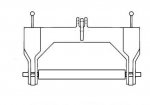

I finally got my Land Pride QH15 and am ready to use it this weekend. It came with one set of bushings to fit over my lift pins on 1 implement.

Looking at the cost of the quick hitch adapter kits ranging from $15 to $30 per set. Or just buying the bushings to build up the lift pins as another option.

Why not just buy the correct size lift pins and install them on the implements?

I only see posts saying to install the kit or bushings but no discussion unless I just overlooked it on replacing the lift pins.

Educate me as to why I would not just replace the lift pins as the price to do so depending on the where purchased, the lift pins run less than the kit.

I understand building up the pins with bushings along is cheaper but cheaper is not always better.

Thanks for your time.

Jay

I have read many posts on the use and brands of QH but have not seen this discussed.

I finally got my Land Pride QH15 and am ready to use it this weekend. It came with one set of bushings to fit over my lift pins on 1 implement.

Looking at the cost of the quick hitch adapter kits ranging from $15 to $30 per set. Or just buying the bushings to build up the lift pins as another option.

Why not just buy the correct size lift pins and install them on the implements?

I only see posts saying to install the kit or bushings but no discussion unless I just overlooked it on replacing the lift pins.

Educate me as to why I would not just replace the lift pins as the price to do so depending on the where purchased, the lift pins run less than the kit.

I understand building up the pins with bushings along is cheaper but cheaper is not always better.

Thanks for your time.

Jay