Tractor NUG

Member

Equipment

B2601, LA434 Loader, B2782B Snowblower, RB1672 Rear Blade,TowBar,HLA 60" Grapple

Good morning folks,

I will try not to get too wordy but I have searched the site and see there are scattered posts here and there about ballast, but no dedicated thread. There are helpful opinions both supporting the need to use rear ballast boxes/rear mounted weight, as well as just as many suggesting it is not necessary. Since this seems to be a very debatable subject, I was hoping folks could provide their opinions here in a new Thread dedicated to Ballast. Here is the scenario:

I am new to tractors and just got my very first one (as some may have seen). It is B2601- with a loader (LA434), A 63" front mounted snowblower and a 60" HLA Attachments Root Rake/Grapple. (It's awesome - I can't stay off it)

I did a lot of research- internet / dealerships, YouTube etc and when I finally got down to purchasing my equipment, the Dealer suggested I fill the back tires with beet juice- which I did.

As we went through the implements I wanted to purchase, I requested a Ballast Box- the dealer told me I did not need a ballast box. In short, he said the implements are sized to the tractor and its capacities and that normally I should not need any ballast behind the tractor when using the loader or snowblower etc. The rear tires are filled to provide extra weight and stability and short of any odd scenarios, or if I find for example, that I am slipping on steep hills while snowblowing the driveway in the winter, I should not need to put any weight on the back. Hence, he did not try to sell me a ballast box.

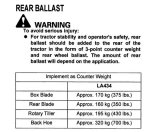

Since then I have received some great support and advice from many folks on the forum- many suggesting I need/must put ballast on the rear to offset weight I put on the front. I also consulted my Owner's Manual (as was suggested by one of you) and the manual has very little on ballast and does not spec that it is required or provide any specs on how much etc, but recommends filling the rear tires and that rear ballast should be used temporarily when necessary and then removed from the tractor. It is literally one sentence in the Manual.

In both the Owner's manual and the Loader Manual, they talk about the lift capacity of the loader (maximum weight etc) but neither manual mentions anything about the need to add rear ballast when using the Loader.

I have read the links provided by some of you and comments and at one end of the argument, there is information about the "pivot" point created by weight, and that it should not be put on the front axle (and the absence of ballast behind the rear axle will create this condition), to the other end of the debate in which the opinion was that putting a ballast box behind the rear axle creates undue strain on the rear axle and should not be used.

Just spoke to my excavator this morning. Seized the opportunity and asked him the question, and he told me unequivocally, that I do NOT need to put ballast on the back of the tractor when using the loader etc in the front. He said it was unnecessary and the implements are sized to the tractor. He is a 2nd generation excavator and has various sizes of tractors from small to huge CATs.

My dealer is also a 2nd generation farm equipment outfit and said it was not needed.

So, new guy here and still not sure which view to adopt.

I would love to settle this debate. The forum is open....please share your views

Cheers and thanks!

I will try not to get too wordy but I have searched the site and see there are scattered posts here and there about ballast, but no dedicated thread. There are helpful opinions both supporting the need to use rear ballast boxes/rear mounted weight, as well as just as many suggesting it is not necessary. Since this seems to be a very debatable subject, I was hoping folks could provide their opinions here in a new Thread dedicated to Ballast. Here is the scenario:

I am new to tractors and just got my very first one (as some may have seen). It is B2601- with a loader (LA434), A 63" front mounted snowblower and a 60" HLA Attachments Root Rake/Grapple. (It's awesome - I can't stay off it)

I did a lot of research- internet / dealerships, YouTube etc and when I finally got down to purchasing my equipment, the Dealer suggested I fill the back tires with beet juice- which I did.

As we went through the implements I wanted to purchase, I requested a Ballast Box- the dealer told me I did not need a ballast box. In short, he said the implements are sized to the tractor and its capacities and that normally I should not need any ballast behind the tractor when using the loader or snowblower etc. The rear tires are filled to provide extra weight and stability and short of any odd scenarios, or if I find for example, that I am slipping on steep hills while snowblowing the driveway in the winter, I should not need to put any weight on the back. Hence, he did not try to sell me a ballast box.

Since then I have received some great support and advice from many folks on the forum- many suggesting I need/must put ballast on the rear to offset weight I put on the front. I also consulted my Owner's Manual (as was suggested by one of you) and the manual has very little on ballast and does not spec that it is required or provide any specs on how much etc, but recommends filling the rear tires and that rear ballast should be used temporarily when necessary and then removed from the tractor. It is literally one sentence in the Manual.

In both the Owner's manual and the Loader Manual, they talk about the lift capacity of the loader (maximum weight etc) but neither manual mentions anything about the need to add rear ballast when using the Loader.

I have read the links provided by some of you and comments and at one end of the argument, there is information about the "pivot" point created by weight, and that it should not be put on the front axle (and the absence of ballast behind the rear axle will create this condition), to the other end of the debate in which the opinion was that putting a ballast box behind the rear axle creates undue strain on the rear axle and should not be used.

Just spoke to my excavator this morning. Seized the opportunity and asked him the question, and he told me unequivocally, that I do NOT need to put ballast on the back of the tractor when using the loader etc in the front. He said it was unnecessary and the implements are sized to the tractor. He is a 2nd generation excavator and has various sizes of tractors from small to huge CATs.

My dealer is also a 2nd generation farm equipment outfit and said it was not needed.

So, new guy here and still not sure which view to adopt.

I would love to settle this debate. The forum is open....please share your views

Cheers and thanks!