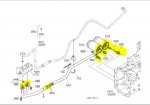

I'm Guessing if I remove the pump I will find no oring at all, or a damaged one^I just checked my itemized invoice from pump replacement at the dealer. They did not replace oring 020 in bottom picture. The only o rings they replaced were the 2 pressure orings on top of pump

Sent from my SM-G900V using Tapatalk

M6800SDT 4WD CAB - Engine oil Problem

- Thread starter JbirdM6800

- Start date

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

Ok, now I just gotta repost what I already posted but later deleted. In one of the early replies to your first post. I had asked if the oil level in the transmission was increasing. My post said that its a big reservoir and would hold quite a lot before there were obvious symptoms of being too full. But I thought it bordered on being obvious and maybe disrespectful , so I just deleted it. Checking in just now I see it was on the right track.

There aren't many ways engine oil can get into the trans unless some tubing somewhere is connected wrong - like on a crankcase oil cooler. OR, if the oil is being put in the wrong opening (way too obvious but I've already learned there's no such thing.)

There aren't many ways engine oil can get into the trans unless some tubing somewhere is connected wrong - like on a crankcase oil cooler. OR, if the oil is being put in the wrong opening (way too obvious but I've already learned there's no such thing.)

Last edited:

coachgeo

Well-known member

Equipment

L225 w/woods Few Mowers & Back Blade, D722 in Motorcycle (Triumph Tiger), LMTV

yup yup.... BIG supporter of self-moderating. Went ahead and cleaned up things while I was here though.you can delete and edit your own posts, no need to ask mod. Go to the post in question and click on "edit".

Thanks, I understand. I did check all lines and compared to service manual skematics. The oil cooler is correct. All lines are correct. I am sure I am putting oil in crankcase as the fill port is right next to the dipstick above engine oil pan on the side of engine.

It appears there is a small oring that seals the spline of the pump when it is inserted into female shaft on pump mounting base. (See drawings above). I will take it apart tomorrow and update.

I am disappointed the dealer would not change this oring when they changed the pump.

I'm beginning to think this may have been the same problem all along and the original pump was good

Sent from my SM-G900V using Tapatalk

It appears there is a small oring that seals the spline of the pump when it is inserted into female shaft on pump mounting base. (See drawings above). I will take it apart tomorrow and update.

I am disappointed the dealer would not change this oring when they changed the pump.

I'm beginning to think this may have been the same problem all along and the original pump was good

Sent from my SM-G900V using Tapatalk

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

Your problem will not be from any of those o-rings.

It will be from the main seal in the end of the pump.

It will be from the main seal in the end of the pump.

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

Hi Wolfman, does the front case on this engine (4 cyl 3.3L) get forced engine oil or is it a splash system? Is the forward pump chamber steering or main hydraulics? The suction side of the forward chamber's seal must be getting submerged in engine oil somehow (??)Your problem will.........be from the main seal in the end of the pump.

The front Chamber of pump is for the Hydraulics, the rear is for the Power Steering.Hi Wolfman, does the front case on this engine (4 cyl 3.3L) get forced engine oil or is it a splash system? Is the forward pump chamber steering or main hydraulics? The suction side of the forward chamber's seal must be getting submerged in engine oil somehow (??)

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

maybe the replacement pump has some bad or missing internal parts? I like your idea about the small o-ring being missing or damaged - allowing oil to get sucked in, assuming there's a supply (rank guess)?..........this may have been the same problem all along and the original pump was good......

Last edited:

I'm Not Sure, The original problem when I bought it was "no hydraulics at idle, and they began working over 1000-1200 rpms. I did not own the tractor that long and since this was my first tractor with loader hydraulics, I called my local dealer to service. Technician came to my farm and did a complete service. Changed engine oil and filters, Hydraulic oil and filters, Fuel filters, fan belts etc. When Changing the hydraulic oil he mentioned that it was extremely black, and stated that it could have been under heavy load for a while and never changed. I didn't think anything of it. When he put new oil in it was foaming so bad that it was pouring out the dipstick. He put a gauge in the rear accessory attachment and checked pressure. it read 2500-2600 PSI, he stated to me that it should be 3500 and that the pump was bad and cavitation was causing all the foam. No further diagnosis on his part, the service manager scheduled a pickup to change pump.maybe the replacement pump has some bad or missing internal parts?

You can already see why I'm skeptical, Technician told me 3500 psi and when i checked the manual it is a 2500 PSI pump.

When I got the tractor back 2 weeks later, I blew 3 hydraulic hoses on the frontend loader in first hour of operation over a 2 day weekend period. When I called the service dept to explain that i thought something else was wrong, they told me that the hoses were old and that the new pump was probably finding weak points. I replaced every hose on the loader (mind you, the oem hoses were rated for 3000 PSI). The foaming never went away, I have been battling this "air" in hydraulics since late January. Pump was changed in December but I did not have time to even start the tractor until later in January.

I replaced all orings on suction pipe (5 total), changed hydro filters again, and on and on.

It appears as though the engine oil mixing could have been causing the hydro problem all along?

I'm not sure if it matters, but the previous owner said he had trouble with hydraulics right after he bought it like within the first week of operation, and his dealer put "new seals in the pump" and he said it has been fine ever since, that was back in 2008. He was not exactly sure what was changed out.

Sorry for the long post, I'm just trying to give as much info as I can.

I'm really skeptical of dealers technicians ability to troubleshoot and do not want to go down the $$ rabbit hole of changing parts, especially at a dealer rate.

I have been around engines, transmissions, motorcycles, ATV's, etc my whole life. I have rebuilt several gasoline engines, I try to be very humble and ask questions when I encounter something new such as diesels and hydraulics, I have basic knowledge of hydraulics and even less about diesel engines and am by no means an expert.

So in summary,

A machine with 700 hrs has had

1 New pump at factory (0 hrs)

2 New pump from factory rebuilt with seals (0-10hrs)

3 A replaced pump New at 709 hrs

4 a bad replaced pump. (currently)

seems to me something is being missed

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

I'm not an expert either. Black hydraulic fluid isn't common in a gear tractor, even one that's been used hard. But foamy black fluid would certainly be expected if crankcase oil was being sucked through a damaged or missing pump seal and going into the transmission.I'm Not Sure, The original problem when I bought it was "no hydraulics at idle, and they began working over 1000-1200 rpms. I did not own the tractor that long and since this was my first tractor with loader hydraulics, I called my local dealer to service. Technician came to my farm and did a complete service. Changed engine oil and filters, Hydraulic oil and filters, Fuel filters, fan belts etc. When Changing the hydraulic oil he mentioned that it was extremely black, and stated that it could have been under heavy load for a while and never changed. I didn't think anything of it. When he put new oil in it was foaming so bad that it was pouring out the dipstick. He put a gauge in the rear accessory attachment and checked pressure. it read 2500-2600 PSI, he stated to me that it should be 3500 and that the pump was bad and cavitation was causing all the foam. No further diagnosis on his part, the service manager scheduled a pickup to change pump.

You can already see why I'm skeptical, Technician told me 3500 psi and when i checked the manual it is a 2500 PSI pump.

When I got the tractor back 2 weeks later, I blew 3 hydraulic hoses on the frontend loader in first hour of operation over a 2 day weekend period. When I called the service dept to explain that i thought something else was wrong, they told me that the hoses were old and that the new pump was probably finding weak points. I replaced every hose on the loader (mind you, the oem hoses were rated for 3000 PSI). The foaming never went away, I have been battling this "air" in hydraulics since late January. Pump was changed in December but I did not have time to even start the tractor until later in January.

I replaced all orings on suction pipe (5 total), changed hydro filters again, and on and on.

It appears as though the engine oil mixing could have been causing the hydro problem all along?

I'm not sure if it matters, but the previous owner said he had trouble with hydraulics right after he bought it like within the first week of operation, and his dealer put "new seals in the pump" and he said it has been fine ever since, that was back in 2008. He was not exactly sure what was changed out.

Sorry for the long post, I'm just trying to give as much info as I can.

I'm really skeptical of dealers technicians ability to troubleshoot and do not want to go down the $$ rabbit hole of changing parts, especially at a dealer rate.

I have been around engines, transmissions, motorcycles, ATV's, etc my whole life. I have rebuilt several gasoline engines, I try to be very humble and ask questions when I encounter something new such as diesels and hydraulics, I have basic knowledge of hydraulics and even less about diesel engines and am by no means an expert.

So in summary,

A machine with 700 hrs has had

1 New pump at factory (0 hrs)

2 New pump from factory rebuilt with seals (0-10hrs)

3 A replaced pump New at 709 hrs

4 a bad replaced pump. (currently)

seems to me something is being missed

Kubota hydraulic pumps are not complicated. There are plenty of pics and videos on the net showing what gear pumps typically look like inside. If a seal is missing or damaged it should be easy to spot. I'd open it up, clean and inspect it, and post pics of what's found. If the inside of the housing and hard parts look reasonably smooth and if gear tooth tip clearance is near spec, replace any missing seals or any that look questionable, put it back together and test it for enough time to see if its still pumping engine oil into the transmission. My bet is you'll be able to cure this just using common sense.

As always, prompt cheerful refund if advice is bogus. Take care, Dick B.

Last edited:

Thanks for all the help.

I will post some updates this evening

Sent from my SM-G900V using Tapatalk

I will post some updates this evening

Sent from my SM-G900V using Tapatalk

Daren Todd

Well-known member

Lifetime Member

Equipment

Massey Ferguson 1825E, Kubota Z121S, Box blade, Rotary Cutter

I did have a thought last night. Check your case vent on the valve cover. Make sure it's venting freely.

I've had a couple motors start losing oil from weird and strange places. What I found was a bad pcv valve.

Engine started building pressure and started pushing motor oil out in the weakest spot. It's basically the equivalent of capping off all orifices and pressurizing the engine with an air chuck.

Sent from my iPhone using Tapatalk

I've had a couple motors start losing oil from weird and strange places. What I found was a bad pcv valve.

Engine started building pressure and started pushing motor oil out in the weakest spot. It's basically the equivalent of capping off all orifices and pressurizing the engine with an air chuck.

Sent from my iPhone using Tapatalk

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

That occurred to me too - but the main crank seal is a pretty easy escape for a pressurized crankcase and the clutch housing was reported dry.

Daren Todd

Well-known member

Lifetime Member

Equipment

Massey Ferguson 1825E, Kubota Z121S, Box blade, Rotary Cutter

I had one work it's way through a seal in a turbo on a 300hp engine.That occurred to me too - but the main crank seal is a pretty easy escape for a pressurized crankcase and the clutch housing was reported dry.

Main seal may not be the weakest point on the system

Well here it is folks. The oils seal on pump shaft was blown out at the ID.

So, that leaves me to wonder...

Poor instalation of seal from factory?

Defective seal on new pump?

Or

Pump is remanufactured and shaft is bad?

I have a new seal coming in the morning,

I will install and keep you posted.

Sent from my SM-G900V using Tapatalk

So, that leaves me to wonder...

Poor instalation of seal from factory?

Defective seal on new pump?

Or

Pump is remanufactured and shaft is bad?

I have a new seal coming in the morning,

I will install and keep you posted.

Sent from my SM-G900V using Tapatalk

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

The pump on this model is different than most other tractors in that it sits below the fuel pump and thus is under the oil line and or might be getting oil forced to it from the gears in front of it.Hi Wolfman, does the front case on this engine (4 cyl 3.3L) get forced engine oil or is it a splash system? Is the forward pump chamber steering or main hydraulics? The suction side of the forward chamber's seal must be getting submerged in engine oil somehow (??)

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

Good pictures -

In view of this tractor's difficult hydraulic history it would make sense to take the pump

apart and inspect everything. The damaged seal looks like there could be more damaged

seals further in allowing pressure to get to the outside seal.

At some point in the past the system may have been dead-headed without a functioning

relief valve, possibly damaging the internal seals. Normally the relief valves protect the pump

unless defeated or bypassed somehow (log splitter? pump testing?)

The 060 seal kit 35890-12970 contains the internal seals at the gears - 2 kits per chamber.

Good luck - and good doing so far.. Take care, Dick B

In view of this tractor's difficult hydraulic history it would make sense to take the pump

apart and inspect everything. The damaged seal looks like there could be more damaged

seals further in allowing pressure to get to the outside seal.

At some point in the past the system may have been dead-headed without a functioning

relief valve, possibly damaging the internal seals. Normally the relief valves protect the pump

unless defeated or bypassed somehow (log splitter? pump testing?)

The 060 seal kit 35890-12970 contains the internal seals at the gears - 2 kits per chamber.

Good luck - and good doing so far.. Take care, Dick B

Attachments

-

153.7 KB Views: 429

Last edited:

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

I would be checking the relief valve, a bad Valve could be causing the pump to over pressure and blow the seals.Well here it is folks. The oils seal on pump shaft was blown out at the ID.

So, that leaves me to wonder...

Poor instalation of seal from factory?

Defective seal on new pump?

Or

Pump is remanufactured and shaft is bad?

I have a new seal coming in the morning,

I will install and keep you posted.

Also a pump can blow the seals if it cavitates and sucks air.

Have you replaced all the O-rings that seal the system?

I would also be doing a pressure test.

There will also be relief valve in the loader valve that could be bad and causing you issues too.

Relief Valve:

Suction line seal points:

Attachments

-

38.2 KB Views: 431

-

35.4 KB Views: 523

The original problem before pump replacement was air in the system. Dealer only replaced pump and 2 pressure side o rings on top side of pump.

When new pump was installed, I blew 3 loader hoses in the first hour of operation. 1 hose for loader lift, 2nd was the short supply hose from pressure line to loader control valve. 3rd was on tilt of bucket.

I ended up changing all loader hoses, including both supply hoses and big return line on loader control.

With that said, the foam would return (visible on hydraulic dipstick) immediately after starting tractor. I believed the air being compressed is what was blowing hoses. I then replaced the five orings sealing the suction line. At this point the foam seemed to be gone after a short run. Different from before when foam would return immediately. So, I assumed I fixed the problem. Well, that brings me to the engine oil problem we are currently dealing with. I did not run the tractor hard or for very long periods prior to this point for fear of air bubbles in hydro fluid causing damage.

So.... here we are with what I believe is a sealed suction line and a blown front seal on pump.

Next steps????

I have new seal coming today for pump shaft.

Should I disassemble rest of pump?

What is best way to test pressure relief valve on PTO and loader? Or should I just change them?

I should also note: the dealer technician (prior to pump install) checked pressure on the accessory port on top of PTO and it read just over 2500 PSI while lever was held open.

I appreciate any and all feedback.

Sent from my SM-G900V using Tapatalk

When new pump was installed, I blew 3 loader hoses in the first hour of operation. 1 hose for loader lift, 2nd was the short supply hose from pressure line to loader control valve. 3rd was on tilt of bucket.

I ended up changing all loader hoses, including both supply hoses and big return line on loader control.

With that said, the foam would return (visible on hydraulic dipstick) immediately after starting tractor. I believed the air being compressed is what was blowing hoses. I then replaced the five orings sealing the suction line. At this point the foam seemed to be gone after a short run. Different from before when foam would return immediately. So, I assumed I fixed the problem. Well, that brings me to the engine oil problem we are currently dealing with. I did not run the tractor hard or for very long periods prior to this point for fear of air bubbles in hydro fluid causing damage.

So.... here we are with what I believe is a sealed suction line and a blown front seal on pump.

Next steps????

I have new seal coming today for pump shaft.

Should I disassemble rest of pump?

What is best way to test pressure relief valve on PTO and loader? Or should I just change them?

I should also note: the dealer technician (prior to pump install) checked pressure on the accessory port on top of PTO and it read just over 2500 PSI while lever was held open.

I appreciate any and all feedback.

Sent from my SM-G900V using Tapatalk

rbargeron

Well-known member

Lifetime Member

Equipment

L5450, L48, L3250, L345 never enough attachments

If so please see posts #37 and #38 & attachments above........I appreciate any and all feedback.........

The next step is taking the pump further apart to learn more

about what made the seal blow out from the inside.

Keep in mind the engine oil has been going IN there, not out.

The damaged seal is a symptom. The cause is still unknown.

Last edited: