Ok, here we go......

I got new pump.

Disassembled pump mount to clean and check idler gear and bearing, all is ok. I had some metal between pump and mounting base from shaft shearing. All was cleaned and reassembled. Flushed entire suction line incase any metal from gears in pump fell down. The original pump was bad when I put it on. I could turn the shaft fairly easily, unlike the new pump that has quite some resistance.

I reinstalled new pump with all new orings (suction and delivery). I start the tractor and check pressure at rear accessory port. At idle, 500-600 RPMS ,

I get 2400 psi. The front loader moves up and down great, however I limited the range and use of loader until I test it.

All seems well.

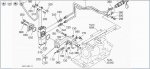

Here's where it gets interesting. I pulled the relief valve, however there is no jamb nut or adjust, as shows in diagram below. It is just a solid plug. It has a cylindrical shaft with an oring and backup seal at the end of it. It is not what is in the diagram no adjustment or internal parts at all. I called Messicks Service line and gave them my serial numbers, and they claim it should be what's in the diagram.

I put the gauge on my lift side outlet port. If I start the tractor and just bump the lift lever it pegs my gauge past 5000psi.

I can take more pictures if nessessary.

Am I testing properly?

How could a setup like this work for 700 hrs?

I will remove the relief valve under the return line and take some good pictures, it is definitely not what is in the diagram.

Sent from my SM-G900V using Tapatalk

I got new pump.

Disassembled pump mount to clean and check idler gear and bearing, all is ok. I had some metal between pump and mounting base from shaft shearing. All was cleaned and reassembled. Flushed entire suction line incase any metal from gears in pump fell down. The original pump was bad when I put it on. I could turn the shaft fairly easily, unlike the new pump that has quite some resistance.

I reinstalled new pump with all new orings (suction and delivery). I start the tractor and check pressure at rear accessory port. At idle, 500-600 RPMS ,

I get 2400 psi. The front loader moves up and down great, however I limited the range and use of loader until I test it.

All seems well.

Here's where it gets interesting. I pulled the relief valve, however there is no jamb nut or adjust, as shows in diagram below. It is just a solid plug. It has a cylindrical shaft with an oring and backup seal at the end of it. It is not what is in the diagram no adjustment or internal parts at all. I called Messicks Service line and gave them my serial numbers, and they claim it should be what's in the diagram.

I put the gauge on my lift side outlet port. If I start the tractor and just bump the lift lever it pegs my gauge past 5000psi.

I can take more pictures if nessessary.

Am I testing properly?

How could a setup like this work for 700 hrs?

I will remove the relief valve under the return line and take some good pictures, it is definitely not what is in the diagram.

Sent from my SM-G900V using Tapatalk