I just got my new L3301HST with BH77 backhoe a few days ago. On delivery day, the dealer and I took off the backhoe to mount up one of my 3-point implements for training purposes, and yesterday I put the backhoe back on. Mounting the backhoe is trickier than the Youtube videos I've seen suggest, since those folks just uncouple, drive straight forward and straight back, then recouple! I also didn't realize that it's necessary to grab a couple of wrenches to remove the 3 point links. I think I'll get some spare bolts and nuts for that, because the lower link pin bolts and telescoping stabilizer nuts/bolts look easy to lose.

I have a question about the proper alignment of the backhoe, subframe, and pins. I had a hard time getting everything lined up to remount the backhoe, since this was my first time doing it. I needed to tap the left pin into place, while the right pin easily slid in by hand. I'm not sure what the alignment is supposed to look like between the backhoe and the subframe. Here's what mine looks like after I put the backhoe on:

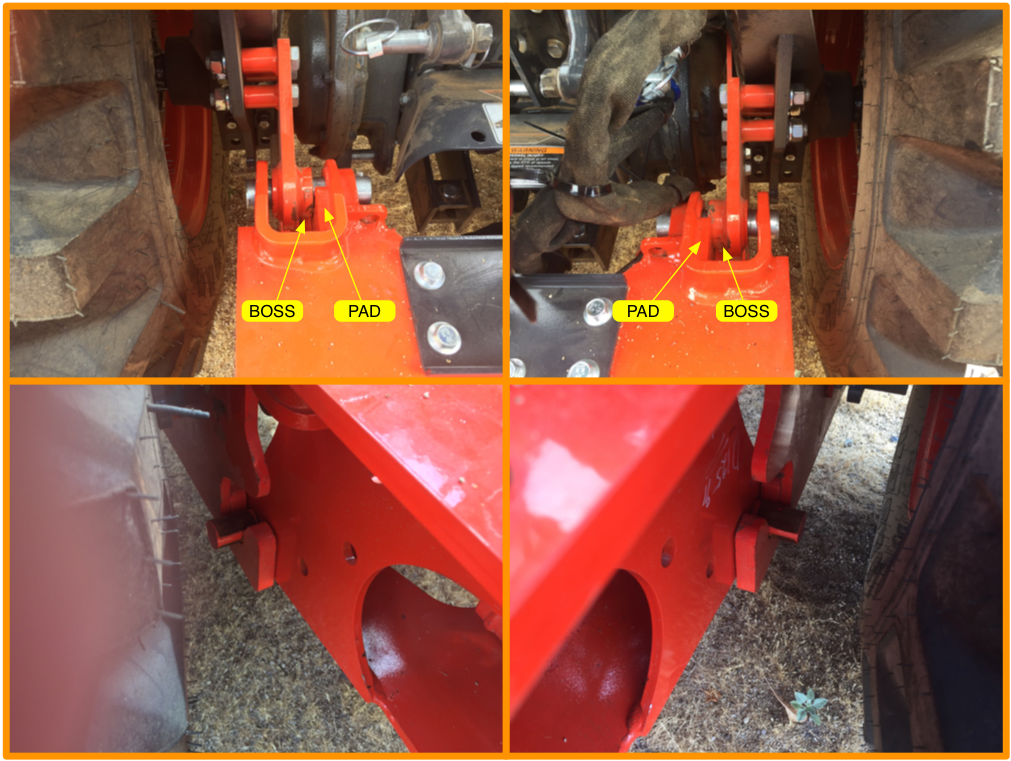

Should the bosses around the subframe pin holes bump into the pads on the inner sides of the backhoe brackets? The way it's all lined up looks funny to me. I'd expect the subframe spacing to either have both bosses solidly contact the pads (i.e., subframe brackets closer to each other), or have both bosses clear the pads (i.e., subframe brackets farther apart from each other). As mine currently sits, the left side boss just barely clears the pad, and the right side boss just barely contacts it.

I have a question about the proper alignment of the backhoe, subframe, and pins. I had a hard time getting everything lined up to remount the backhoe, since this was my first time doing it. I needed to tap the left pin into place, while the right pin easily slid in by hand. I'm not sure what the alignment is supposed to look like between the backhoe and the subframe. Here's what mine looks like after I put the backhoe on:

Should the bosses around the subframe pin holes bump into the pads on the inner sides of the backhoe brackets? The way it's all lined up looks funny to me. I'd expect the subframe spacing to either have both bosses solidly contact the pads (i.e., subframe brackets closer to each other), or have both bosses clear the pads (i.e., subframe brackets farther apart from each other). As mine currently sits, the left side boss just barely clears the pad, and the right side boss just barely contacts it.