hi all, just joined this site, always looking for infor on my BX1860 i have owned for three years and have 300 hrs on it. was changing hydrolic filter and checking under for tractor. I found seals on hydro drive shaft from motor were cracked. I ordered them from my dealer and went on line to find the best way to change the seals. It is a major undertaking because you have to take many parts off and lift the motor. So i am thinking why kuboto does not have a seal that is split in have and can be wraped around shaft and clamped. Im sure all the tractors have dust seals like this. I wraped mine with tire tube rubber and camped. Has anyone done this or have a better idea. thanks. I will be on this site alot i can tell that already.

new member and dust seal idea

- Thread starter kenbx1860

- Start date

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

First, if you don't have it, go to Kubotabooks.com and download the WSM for your tractor.

Second, you can not make a 2 piece seal work very well on hydraulic fluid.

Bite the bullet and fix it right, it's worth the effort.

Second, you can not make a 2 piece seal work very well on hydraulic fluid.

Bite the bullet and fix it right, it's worth the effort.

thanks i will look for that info. the seals i was inquiring about are only the dust seals on the drive shaft from the motor to hydro. they are not under any pressure and only cover the coupling where the shaft leaves motor coupling and enters hydro coupling, they cover some sort of ball joint afair that i think is spring loaded. sorry if i led anyone to think they were pressure seals of some kind. I still think a two piece might work if there was one available. And 600$ to 800$ ever three years will drive me crasy. I am still supprised they are worn and cracking as tractor never sits out if not using it and it is in a heated shop all winter.

Last edited:

Russell King

Well-known member

Equipment

L185F, Modern Ag Competitor 4’ shredder, Rhino tiller, rear dirt scoop

Look at "split bearing isolators" for an idea that may be adapted to you need. They can be made with flanged faces if that would help mounting.

The diameter can be custom made to fit the shaft.

Inpro is brass version, Parker-Protech is a different brand made from "plastic" of some type.

The diameter can be custom made to fit the shaft.

Inpro is brass version, Parker-Protech is a different brand made from "plastic" of some type.

The auto industry tried speedy boots on the axle shafts, also referred to as split boots. From a mechanics standpoint they suck, but did the job as a temporary measure. Now as i get older, i like to do things once and hopefully right.

So if rubber is breaking down, what can be done to prevent it? Armor-all? AT205 is a trans treatment, was told it keeps rubber soft too, like door gaskets on vehicles. Or is it brush/debris -possibly guards to help protect vital things. Cant be uv, as they arent in direct sunlight. Must be a quality issue-as in low bidder.

So if rubber is breaking down, what can be done to prevent it? Armor-all? AT205 is a trans treatment, was told it keeps rubber soft too, like door gaskets on vehicles. Or is it brush/debris -possibly guards to help protect vital things. Cant be uv, as they arent in direct sunlight. Must be a quality issue-as in low bidder.

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

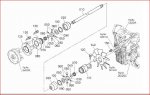

Yea your talking about the 2 CV boots (#20's), they are a bear to change.

But with a little work it can be done right.

and the cost of not doing them up right could be very costly as those 2 joints and shafts are not very cheap to replace because of wear from dirt getting into the joints.

Kubota doesn't skimp on 1/2 repair parts because there is no logic in not repairing it back to the exact condition that it was designed to be.

But with a little work it can be done right.

and the cost of not doing them up right could be very costly as those 2 joints and shafts are not very cheap to replace because of wear from dirt getting into the joints.

Kubota doesn't skimp on 1/2 repair parts because there is no logic in not repairing it back to the exact condition that it was designed to be.

Attachments

-

57.4 KB Views: 560

North Idaho Wolfman

Moderator

Staff member

Lifetime Member

Equipment

L3450DT-GST, Woods FEL, B7100 HSD, FEL, 60" SB, 743 Bobcat with V2203, and more

It can't be that hard to do on a BX.From the looks of it you would have to take the whole body off to get to them,,,,

I can have my L body striped, split and trans pulled in about 4 hours, but then again some think I'm a little off, and I think they are probably right!

hi all, fixed cv boots had to remove all tin and lift motor just not enough room to get the joints apart without doing that on my bx1860. took me about 13 hours. did not have a hoist so had to buy one and put up in shop. should have had one long ago. has anyone put a vent in the filler plug for front axle. Mechanic at shop said after i asked him about my front dif leaking that it is sealed so tight that it builds up pressure and blows oil past seal. Why not vent this. he said is sealed because in places they go so deep in water they have to be sealed, but we dont use it that way. any thoughts.

well it is done. had to take the tractor mostly apart and lift motor as could not get the shaft off otherwise. had to go buy a hoist and install in shop but didnt have one so needed it anyway. took my time and after about thirteen hours back up and running. And it does feel good to do it right.