I purchased a B6100 and it was having some grinding and throwout bearing noise. I adjusted the clutch and was able to get it to work without grinding if I brought the rpms to a very low idle. I greased the throwout bearing but it still was giving that bearing noise. I split the tractor to view both items. I am quite confident that I have to replace the throwout bearing.

I have two questions:

1. After splitting the tractor, I could not get the throwout bearing to release. I read that I had to remove the grease nut bib first so I did that, but it still will not let me pull it out. When I move the clutch pedal it moves in and out. Do I have to remove something else before it allows me to remove it to replace the bearing? Once I get it off, how do I remove the bearing off of that assembly?

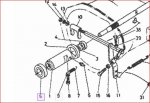

2. Here is a picture of the clutch. How do I know if the clutch is too worn?

I have two questions:

1. After splitting the tractor, I could not get the throwout bearing to release. I read that I had to remove the grease nut bib first so I did that, but it still will not let me pull it out. When I move the clutch pedal it moves in and out. Do I have to remove something else before it allows me to remove it to replace the bearing? Once I get it off, how do I remove the bearing off of that assembly?

2. Here is a picture of the clutch. How do I know if the clutch is too worn?

Attachments

-

43.9 KB Views: 768